No content found!

New Features Stair Design

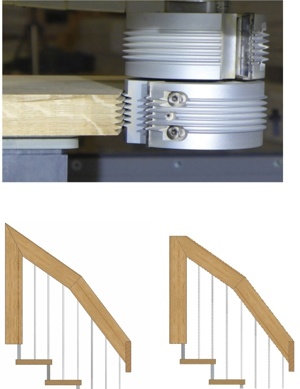

It is now possible to create bent components for stairs of any kind. This construction method is mainly used in handrail-supporting bolt stairs. On the one hand, this is implemented for optical aspects, but, on the other hand, to achieve a more economic production of the components, too. After all, it is naturally easier and faster to produce straight components than curved ones.

The component connections are often connected with so-called mini finger joints. These connections can be easily manufactured on a CNC with the SEMA connect solution for machine connection. This ensures a consistent workflow from design to production.

Another new feature is the punching of timber components in all planes. The benefit can be shown easily and quickly at the handrail-supporting bolt stair, for example, to allow a clean finish for the connecting balustrading. The handrail and post is simply punched at the desired height resulting in a shapely finish.

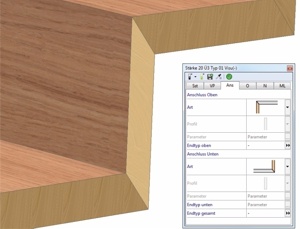

Some new features have been developed for risers, too. So, it is now quite easy to set a mitre between the riser and the tread and to produce it accordingly. The riser will then easily be cut to length with a saw.